-

×

Chint Contactor 3 Pole 25 Amp NXC-25 in PAKISTAN

1 × ₨ 3,300.0

Chint Contactor 3 Pole 25 Amp NXC-25 in PAKISTAN

1 × ₨ 3,300.0 -

×

Schneider MCB 3 pole Miniature Circuit Breaker (iC60N)

1 × ₨ 1,500.0

Schneider MCB 3 pole Miniature Circuit Breaker (iC60N)

1 × ₨ 1,500.0 -

×

Thermocouple Holder K-type (WRNT-202) Fixed Spring in Pakistan

1 × ₨ 500.0

Thermocouple Holder K-type (WRNT-202) Fixed Spring in Pakistan

1 × ₨ 500.0 -

×

Crimper Plier press thimble press HS6L in Pakistan

1 × ₨ 2,000.0

Crimper Plier press thimble press HS6L in Pakistan

1 × ₨ 2,000.0 -

×

Automatic Drain Valve Air Compressor GPH OPT-A 1/2" in Pakistan

1 × ₨ 4,200.0

Automatic Drain Valve Air Compressor GPH OPT-A 1/2" in Pakistan

1 × ₨ 4,200.0

Pneumatic Nozzle PC Connector 16-3 16mmx3/8″ in Pakistan

₨ 190.0

دکاندار حضرات ہول سیل ریٹ اور بلٹی کے معاملات کے لیے اس نمبر پر واٹس ایپ/ کال کرے 03001178484

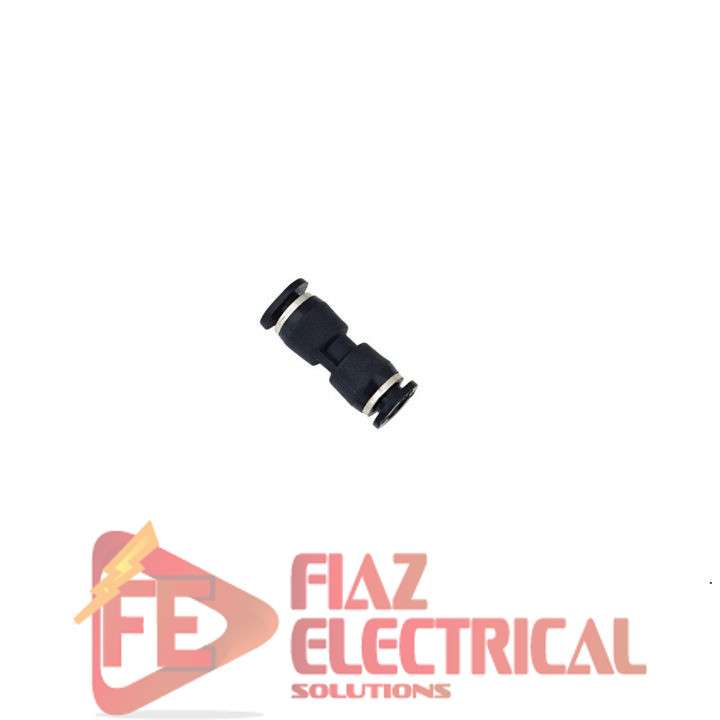

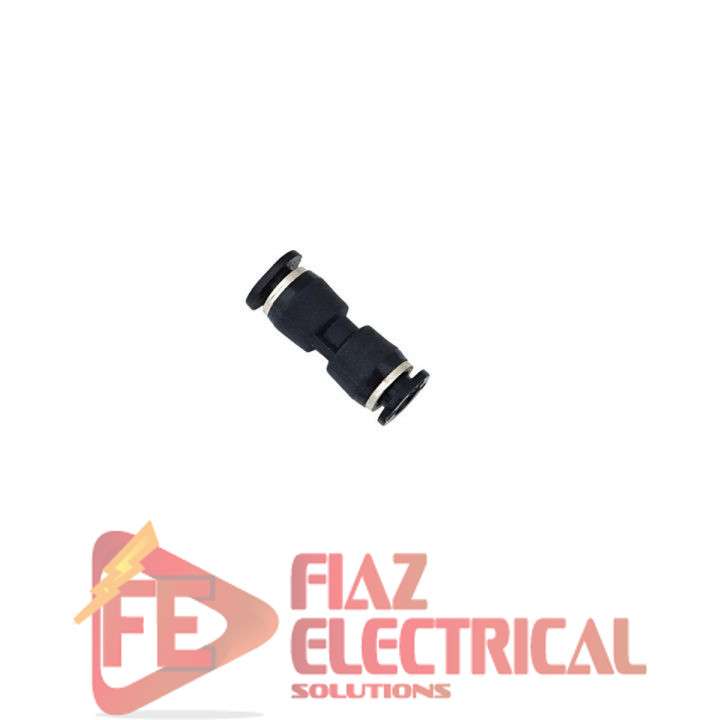

- Introducing the Pneumatic Nozzle PC Connector 16-3 16mmx3/8″ in Pakistan, the perfect solution for all your pneumatic needs.

- This high-quality connector effortlessly combines durability and functionality to ensure seamless operations.

- Crafted with precision, this PC connector is designed to provide a secure and reliable connection between pipes.

- Its 16mmx3/8″ dimensions make it compatible with a wide range of pneumatic systems, offering versatility and convenience.

- Made from premium materials, this connector guarantees long-lasting performance even in challenging environments.

- Its sturdy construction ensures leak-free connections, allowing for efficient airflow and preventing any disruptions in your workflow.

Pneumatic Nozzle PC Connectors

As a professional in the field of pneumatic systems, I understand the importance of choosing the right components for optimal performance. One such crucial component is the pneumatic nozzle PC connector. In this comprehensive guide, I will provide you with all the information you need to find the best Pneumatic Nozzle PC Connector 16-3 16mmx3/8″ in Pakistan.

A pneumatic nozzle PC connector is a vital part of any pneumatic system. It connects the nozzle to the PC, allowing for the smooth and efficient flow of compressed air. These connectors come in various sizes and specifications to accommodate different systems and applications. The 16-3 16mmx3/8″ size is a popular choice due to its versatility and compatibility with a wide range of pneumatic equipment.

Understanding the 16-3 16mmx3/8″ size

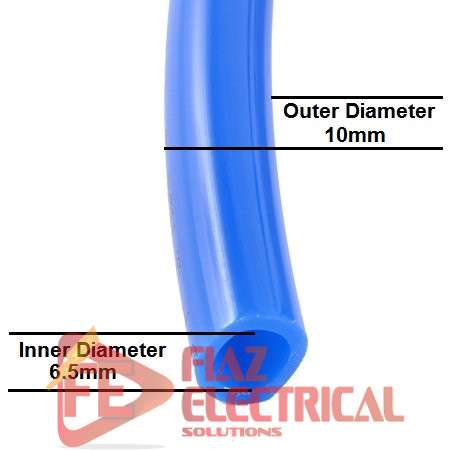

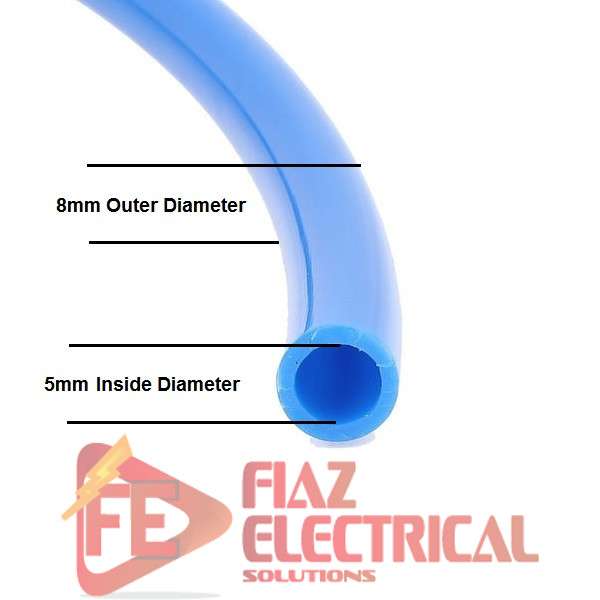

The 16-3 16mmx3/8″ size refers to the dimensions of the pneumatic nozzle PC connector. The first number, 16-3, represents the outside diameter of the connector, which is 16mm. The second number, 16mmx3/8″, specifies the thread size of the connector, which is 3/8 inch. It is essential to understand these dimensions to ensure compatibility with your existing pneumatic system.

The 16-3 16mmx3/8″ size is commonly used in various industries, including manufacturing, automotive, and construction. It offers a balance between airflow capacity and compactness, making it suitable for both small and medium-sized pneumatic systems. Whether you are connecting air tools, pneumatic cylinders, or other pneumatic equipment, the 16-3 16mmx3/8″ size is a versatile option.

Importance of choosing the right pneumatic nozzle PC connector

Selecting the right pneumatic nozzle PC connector is crucial for the overall performance and efficiency of your pneumatic system. A poorly chosen connector can lead to air leaks, reduced airflow, and even system failure.

One of the primary considerations is the material of the connector. It should be durable, corrosion-resistant, and able to withstand high-pressure environments. Brass and stainless steel are common materials used in pneumatic connectors due to their strength and durability.

Another vital factor is the connector’s compatibility with your existing pneumatic system. Ensure that the connector’s size, thread type, and connection method match your system’s requirements. This will ensure a secure and reliable connection, minimizing the risk of leaks or pressure drops.

Additionally, consider the operating conditions and environment in which the connector will be used. Factors such as temperature, humidity, and exposure to chemicals can affect the connector’s performance and lifespan. Choose a connector that is designed to withstand the specific conditions of your application.

Factors to consider when selecting a pneumatic nozzle PC connector

When selecting a Pneumatic Nozzle PC Connector 16-3 16mmx3/8″ in Pakistan, there are several factors you should consider to make an informed decision.

- Size and thread type: Ensure that the connector’s size and thread type are compatible with your pneumatic system.

- Material: Consider the material of the connector and choose one that is durable and resistant to corrosion.

- Connection method: Determine the type of connection method that best suits your application, such as push-to-connect or threaded connection.

- Operating conditions: Take into account the temperature, humidity, and exposure to chemicals in your application environment.

- Pressure rating: Check the connector’s pressure rating to ensure it can handle the maximum pressure of your pneumatic system.

By considering these factors, you can find a pneumatic nozzle PC connector that meets your specific requirements and ensures optimal performance.

How to install and use a pneumatic nozzle PC connector

Installing and using a Pneumatic Nozzle PC Connector 14-4 14mmx1/2″ in is a straightforward process. Here is a step-by-step guide to help you:

- Ensure that the pneumatic system is depressurized before installing the connector. Turn off the air supply and release any remaining pressure in the system.

- Identify the nozzle and PC connection points where the connector will be installed. Clean the connection points to remove any dirt or debris that may affect the seal.

- If using a threaded connector, apply a small amount of thread sealant to the male threads.

- Align the connector with the connection points and hand-tighten it. Use a wrench or pliers to make a final quarter-turn to ensure a tight seal. Avoid over-tightening, as this can damage the connector or the connecting points.

- Once the connector is installed, you can turn on the air supply and test the system for any leaks or abnormalities. Ensure that the air flows smoothly through the connector and there are no leaks at the connection points.

Using a pneumatic nozzle PC connector is as simple as connecting the nozzle to the PC. The secure connection ensures a reliable flow of compressed air, allowing your pneumatic system to operate efficiently.

Common problems and troubleshooting tips for pneumatic nozzle PC connectors

While Pneumatic Nozzle PC Connector 14-4 14mmx1/2” are generally reliable, occasionally, problems may arise. Here are some common issues and troubleshooting tips:

- Air leaks: If you notice air leaks at the connection points, check for loose or damaged connectors. Tighten the connectors or replace them if necessary. Additionally, ensure that the connection points are clean and free from debris.

- Reduced airflow: If the airflow through the connector is reduced, it may be due to a clogged or obstructed connector. Clean the connector thoroughly to remove any dirt or debris.

- Inconsistent performance: If your pneumatic system’s performance is inconsistent, it may be due to a faulty or worn-out connector.

- Pressure drops: If you experience pressure drops in your pneumatic system, check for leaks or loose connections. Tighten the connectors or replace them if needed. Additionally, ensure that the connectors are compatible with the system’s pressure requirements.

Regular maintenance and inspection of your pneumatic nozzle PC connectors can help prevent these problems. Clean the connectors regularly, replace worn-out connectors, and ensure proper installation to maintain optimal performance.

Maintenance and care for pneumatic nozzle PC connectors

To ensure the longevity and optimal performance of your Pneumatic Nozzle PC Connector 14-4 14mmx1/2″, proper maintenance and care are essential.

- Regular cleaning: Clean the connectors regularly to remove any dirt, debris, or contaminants that can affect their performance. Use a mild detergent and a soft brush to clean the connectors gently.

- Inspection: Inspect the connectors periodically for any signs of damage, wear, or corrosion. Replace any connectors that show signs of deterioration to prevent leaks or system failures.

- Lubrication: Apply a small amount of pneumatic lubricant to the connectors to ensure smooth operation and prevent friction.

- Proper storage: When not in use, store the connectors in a clean and dry environment. Avoid exposing them to extreme temperatures, humidity, or corrosive chemicals.

By following these maintenance practices, you can prolong the lifespan of your pneumatic nozzle PC connectors and maintain their optimal performance.

Conclusion and final thoughts

Choosing the right Pneumatic Nozzle PC Connector 14-4 14mmx1/2″ is crucial for the efficient operation of your pneumatic system. Consider factors such as size, material, compatibility, and operating conditions when selecting a connector. Purchase from reputable suppliers and manufacturers to ensure the quality and authenticity of the connectors.

Installation and use of a Pneumatic Nozzle PC Connector 14-4 14mmx1/2″ in Pakistan are straightforward processes, but proper care and maintenance are necessary for optimal performance. Regular cleaning, inspection, and lubrication will help prolong the connectors’ lifespan and prevent issues such as leaks or reduced airflow.

With this ultimate guide, you now have all the information you need to find the best pneumatic nozzle PC connector 16-3 16mmx3/8″ . Choose wisely, install correctly, and maintain regularly to ensure the smooth and efficient operation of your pneumatic system.

| Weight | 0.2 kg |

|---|

1 review for Pneumatic Nozzle PC Connector 16-3 16mmx3/8″ in Pakistan

Add a review Cancel reply

You must be logged in to post a review.

Related products

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 10,500.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 1,550.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Nozzle PC connector 8-2 8mmx1/4″ Pipe PC Connector Pakistan

Rated 5.00 out of 5

₨ 50.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 25.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 45.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 45.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 2,750.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 64.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 33.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Nozzle PC connector 8-3 8mmx3/8″ Pipe PC Connector Pakistan

Rated 5.00 out of 5

₨ 65.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 2,600.0

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Rated 5.00 out of 5

₨ 6,500.0

Schneider MCB 3 pole Miniature Circuit Breaker (iC60N)

Schneider MCB 3 pole Miniature Circuit Breaker (iC60N)  Thermocouple Holder K-type (WRNT-202) Fixed Spring in Pakistan

Thermocouple Holder K-type (WRNT-202) Fixed Spring in Pakistan  Crimper Plier press thimble press HS6L in Pakistan

Crimper Plier press thimble press HS6L in Pakistan  Automatic Drain Valve Air Compressor GPH OPT-A 1/2" in Pakistan

Automatic Drain Valve Air Compressor GPH OPT-A 1/2" in Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting