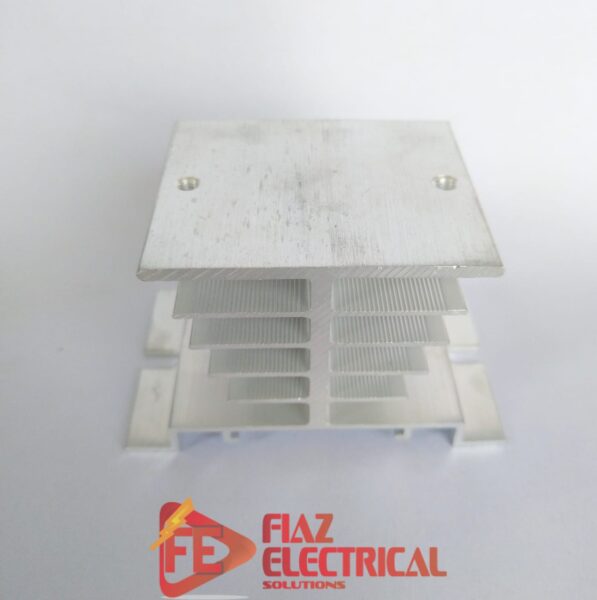

SSR Relay Heat Sink in Pakistan

₨ 380.0

SSR Relay Heat Sink in Pakistan

Product information

| Item Weight | 0.035 ounces |

|---|---|

| Department | unisex-adult |

| Manufacturer | BBAUER |

| ASIN | B0CBFRNF4D |

| Country of Origin | China |

| Import | Country as Labeled |

The Importance of a Heat Sink in Pakistan

Solid State Relays (SSRs) are crucial components in modern electronic circuits. Unlike traditional electromechanical relays, SSRs use semiconductors to switch and control electrical currents. They offer numerous advantages such as faster response times, higher reliability, and longer life spans. However, one crucial aspect that is often overlooked when it comes to SSRs is heat management. In this article, we will explore the significance of heat sinks for SSR Relay Heat Sink in Pakistan and how they can maximize performance.

What is a Heat Sink and Why is it Necessary for SSR Relays?

A heat sink is a passive cooling device that helps dissipate excess heat generated by electronic components, such as SSR relays. It consists of a metal or alloy body with fins or other protruding surfaces that increase its surface area. This increased surface area allows for better heat transfer to the surroundings, thereby preventing overheating and ensuring optimal performance.

Heat sinks are necessary for SSR relays due to the nature of their operation. When an SSR relay is activated, the semiconductor inside it generates heat as a byproduct. If this heat is not dissipated effectively, it can lead to thermal runaway, reduced reliability, and even permanent damage to the SSR relay. Therefore, the installation of a heat sink is essential to maintain safe operating temperatures and maximize the lifespan and performance of SSR relays.

Understanding the Heat Dissipation Process in SSR Relays

To understand the importance of heat sinks, it is crucial to grasp the heat dissipation process in SSR relays. When an SSR relay is in operation, the semiconductor component, typically a thyristor or a triac, experiences a voltage drop and current flow. This voltage drop results in the generation of heat. If the heat is not removed efficiently, it can cause the semiconductor to exceed its maximum operating temperature, leading to failure.

Heat dissipation in SSR relays occurs through conduction, convection, and radiation. Conduction is the transfer of heat through direct contact between the SSR Relay Heat Sink in Pakistan components and the heat sink. Convection involves the transfer of heat through the movement of air or liquid around the heat sink. Radiation is the emission of thermal energy in the form of electromagnetic waves.

The Role of a Heat Sink in Maximizing SSR Relay Performance

A heat sink plays a vital role in maximizing the performance of SSR relays by effectively managing heat dissipation. By providing a large surface area, a heat sink enhances conduction, convection, and radiation, ensuring efficient heat transfer and preventing the SSR relay from overheating.

One of the primary benefits of using a heat sink is its ability to lower the operating temperature of the SSR relay. Keeping the temperature within the appropriate range prevents the degradation of the semiconductor components, leading to enhanced reliability and a longer lifespan for the SSR relay.

Additionally, a heat sink helps maintain the desired electrical characteristics of the SSR relay. Excessive heat can alter the electrical properties of the semiconductor, affecting its switching speed and accuracy. By dissipating heat effectively, a heat sink ensures that the SSR relay functions optimally, providing precise and reliable control over electrical currents.

Types of Heat Sinks Available in Pakistan for SSR Relays

In Pakistan, there are several types of heat sinks available for SSR relays, each suitable for specific applications and environments. The choice of heat sink depends on factors such as power requirements, space constraints, and ambient temperature. Some common types of heat sinks used with SSR relays in Pakistan include:

- Aluminum Heat Sinks: Aluminum heat sinks are lightweight, cost-effective, and widely used for SSR relays in various applications. They offer good thermal conductivity and are available in various shapes and sizes to suit different requirements.

- Copper Heat Sinks: Copper heat sinks provide excellent thermal conductivity and are ideal for applications that require high-performance heat dissipation. However, they are relatively expensive and heavier compared to aluminum heat sinks.

- Heat Pipe Heat Sinks: Heat pipe heat sinks utilize heat pipes to enhance heat transfer efficiency. They are suitable for applications that require superior cooling capabilities, especially in high-power SSR relay systems.

- Fan-cooled Heat Sinks: Fan-cooled heat sinks combine the benefits of a heat sink with an integrated fan for active cooling. They are suitable for environments with limited airflow or high ambient temperatures.

Factors to Consider when Choosing a Heat Sink for SSR Relays in Pakistan

When selecting a SSR Relay Heat Sink in Pakistan, it is important to consider various factors to ensure optimal performance and compatibility.

- Power Dissipation: Determine the power dissipation requirements of the SSR relay and choose a heat sink that can handle the generated heat effectively.

- Thermal Resistance: Consider the thermal resistance of the heat sink, which indicates its ability to transfer heat. Lower thermal resistance leads to better heat dissipation.

- Physical Dimensions: Take into account the available space for installation and choose a heat sink that fits within the given constraints.

- Mounting Options: Check the mounting options provided by the heat sink and ensure compatibility with the SSR relay and the overall system.

- Environmental Factors: Consider the ambient temperature, airflow conditions, and any specific environmental factors that may affect heat dissipation.

Installation and Maintenance Tips for SSR Relay Heat Sinks

Proper installation and regular maintenance of SSR Relay Heat Sink are essential to ensure optimal performance and longevity. Here are some tips to follow:

- Cleanliness: Ensure that the heat sink and SSR relay surfaces are clean and free from dust, debris, or any other contaminants that may hinder heat transfer.

- Thermal Interface Material: Apply an appropriate thermal interface material, such as thermal paste or thermal pads, between the SSR relay and the heat sink to minimize thermal resistance.

- Secure Mounting: Ensure that the heat sink is securely mounted to the SSR relay using the provided mounting mechanism to ensure proper thermal contact.

- Airflow Optimization: Position the SSR relay and heat sink in a way that allows for optimal airflow around the heat sink, maximizing convection and heat dissipation.

- Regular Inspection: Periodically inspect the heat sink for any signs of damage, such as bent fins or corrosion, and replace if necessary.

SSR Relay Heat Sink in Pakistan

Voltage Monitoring Relays

SSR -10AA 25AA 40AA AC Control AC SSR White Shell Single Phase Solid State Relay With Plastic Cover 1Pcs

| Weight | .2 kg |

|---|

Be the first to review “SSR Relay Heat Sink in Pakistan” Cancel reply

You must be logged in to post a review.

Related products

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Revolving Warning Light Siren Sound Red Model No. LTE-1101J in Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Bell Ringer for fire Alarm Bell system safety 6″ round shape in Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Pilot Panel Mount LED Indicator Light 16mm blue Indication light

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Industrial Indication lights, Alarm, sounders, actuators and other output devices Pakistan

Reviews

There are no reviews yet.