Pneumatic Elbow 6-2 6mmx Thread in Pakistan (1/4″)

₨ 60.0

Choosing the Right Pneumatic Elbow

Choosing the right pneumatic elbow 6-2 6mmx thread is essential for the smooth and efficient operation of your pneumatic system. By understanding the different types available, considering important factors, and evaluating customer reviews, you can make a well-informed decision.

Choosing the right pneumatic elbow 6-2 6mmx thread in Pakistan requires careful consideration of several factors. By evaluating these factors, you can ensure that the selected elbow meets your specific requirements and delivers optimal performance.

Pneumatic Elbows and Their Importance

Pneumatic elbows play a crucial role in various industries, including manufacturing, construction, and automation. These essential components are used to redirect the flow of compressed air, allowing for efficient and seamless operation of pneumatic systems. In this comprehensive guide, we will explore everything you need to know about choosing the right Pneumatic Elbow 6-2 6mmx Thread in Pakistan.

Understanding the Different Types of Pneumatic Elbows

Pneumatic elbows come in various types, each designed to meet specific application requirements. It is essential to have a good understanding of the different types available to make an informed decision. The most common types of pneumatic elbows include 90-degree elbows, 45-degree elbows, and swivel elbows.

90-Degree Elbows: These elbows are widely used in pneumatic systems where a right-angle turn is required. They are known for their compact design and are suitable for installations with limited space.

45-Degree Elbows: If you need a less sharp turn in your pneumatic system, 45-degree elbows are the ideal choice. These elbows provide a smoother flow of compressed air and reduce the risk of turbulence. They are commonly used in applications where space is not a constraint, and a gradual change in direction is desired.

Swivel Elbows: Swivel elbows are versatile components that allow for easy adjustment of the direction of airflow. They come with a rotating joint that enables the elbow to swivel, providing flexibility in installations. Swivel elbows are commonly used in applications where frequent changes in direction are required.

Factors to Consider When Choosing a Pneumatic Elbow

Choosing the right pneumatic elbow 6-2 6mmx thread in Pakistan requires careful consideration of several factors. By evaluating these factors, you can ensure that the selected elbow meets your specific requirements and delivers optimal performance. Here are the key factors to consider:

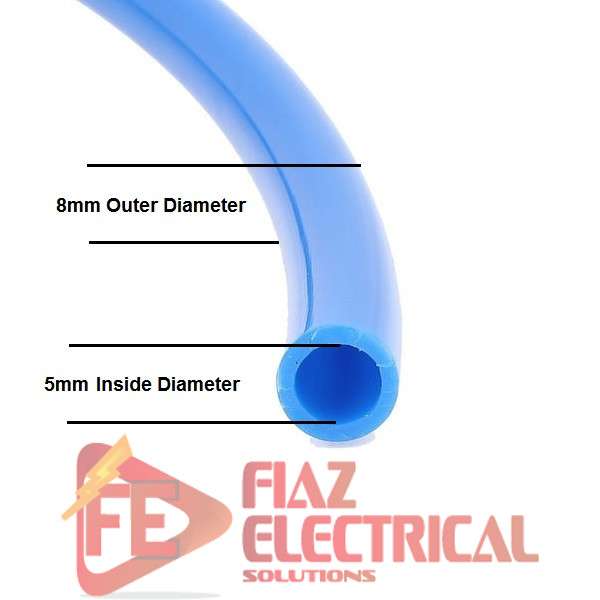

- Size and Compatibility: The size of the pneumatic elbow should match the diameter of the pneumatic tubing or pipe for a secure and leak-free connection. Ensure that the 6-2 6mmx thread (1/4″) size is compatible with your existing system components.

- Material Quality: The material quality of the pneumatic elbow is crucial for longevity and durability. Look for elbows made from high-quality materials such as stainless steel or brass, as they offer excellent resistance to corrosion and wear.

- Pressure and Temperature Ratings: Consider the maximum pressure and temperature limits of the pneumatic elbow. Ensure that it can handle the operating conditions of your system without any risk of failure or performance issues.

- Flow Requirements: Evaluate the required flow rate of your pneumatic system and choose an elbow that can handle the desired airflow without restrictions. A properly sized elbow will minimize pressure drops and maintain system efficiency.

- Application Specifics: Consider the specific application requirements, such as space constraints, environmental factors, and the need for flexibility or adjustability. These factors will help you determine the most suitable type of pneumatic elbow for your application.

Benefits of Using a Pneumatic Elbow 6-2 6mmx Thread (1/4″)

Here are some key advantages:

- Improved Airflow: The design of a pneumatic elbow ensures smooth airflow, reducing turbulence and pressure drops. This leads to enhanced system efficiency and improved performance.

- Leak-Free Connections: A properly installed pneumatic elbow with a 6-2 6mmx thread (1/4″) provides a secure and leak-free connection. This prevents air leakage, ensuring that the system maintains its desired pressure levels.

- Versatility and Flexibility: Pneumatic elbows offer flexibility in system design and installation. With the ability to redirect airflow in different directions, they allow for efficient routing of pneumatic lines, even in complex layouts.

How to Properly Install a Pneumatic Elbow 6-2 6mmx Thread (1/4″)

Proper installation of a pneumatic elbow is crucial for its optimal performance and longevity. Follow these steps to ensure a secure and leak-free installation:

- Prepare the Tubing: Cut the pneumatic tubing to the required length using a tubing cutter. Ensure that the cut is clean and free from burrs or debris.

- Apply Thread Sealant: Apply a thin layer of thread sealant tape or pipe sealant to the male threads of the elbow. This helps create a tight and leak-free seal.

- Hand Tighten: Gently hand tighten the elbow onto the threaded connection. Avoid using excessive force, as it may damage the threads or cause leaks.

- Final Tightening: Use a wrench or a suitable tool to provide the final tightening.

- Check for Leaks: After installation, check for any signs of air leakage around the connection.

Final Thoughts on Choosing the Right Pneumatic Elbow

Choosing the right pneumatic elbow 6-2 6mmx thread is essential for the smooth and efficient operation of your pneumatic system. By understanding the different types available, considering important factors, and evaluating customer reviews, you can make a well-informed decision. Remember to prioritize compatibility, material quality, pressure ratings, flow requirements, and application specifics. . With the right pneumatic elbow, you can enhance the performance, reliability, and longevity of your pneumatic system in Pakistan.

The Pneumatic Elbow 6-1 6mmx Thread plays a vital role in pneumatic systems, providing efficient routing of compressed air and allowing changes in direction. Its compact design, compatibility with standard pneumatic components, and durability make it a versatile fitting suitable for various industries and applications. By understanding its functionality, advantages, and factors to consider when choosing, you can ensure optimal performance and reliable operation of your pneumatic system.

| Weight | 0.1 kg |

|---|

Be the first to review “Pneumatic Elbow 6-2 6mmx Thread in Pakistan (1/4″)” Cancel reply

You must be logged in to post a review.

Related products

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Nozzle PC connector 8-2 8mmx1/4″ Pipe PC Connector Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Nozzle PC connector 8-3 8mmx3/8″ Pipe PC Connector Pakistan

Reviews

There are no reviews yet.