Nozzle Band Heater Injection Molding Machine Heater 50×50 in Pakistan

₨ 850.0

- Introducing the Nozzle Band Heater Injection Molding Machine Heater 50×50 in Pakistan.

- This high-quality heater is designed to optimize your injection molding process, ensuring efficient and precise temperature control.

- Crafted with precision, this heater guarantees uniform heat distribution for consistent results.

- With its compact size and durable construction, this band heater is perfect for injection molding machines.

- 50×50 dimensions make it suitable for a wide range of nozzle sizes, providing a snug fit for optimal heat transfer.

- The innovative design allows for easy installation and removal, saving you valuable time and effort.

Nozzle Band Heater Injection Molding Machine Heater 50×50 in Pakistan

As an experienced professional in the injection molding industry, I understand the importance of having efficient and reliable machinery. One crucial component of injection molding machines is the nozzle band heater, specifically the 50×50 variant, which is widely used in Pakistan. In this comprehensive guide, I will take you through everything you need to know about the Nozzle Band Heater Injection Molding Machine Heater 50×50 in Pakistan.

Understanding the importance of nozzle band heaters in injection molding machines

Nozzle band heaters play a vital role in the injection molding process. These heaters are responsible for maintaining the desired temperature of the nozzle, ensuring proper melt flow and preventing premature cooling. The 50×50 variant is specifically designed to fit the standard size of nozzles commonly used in injection molding machines in Pakistan.

By maintaining a consistent temperature, the nozzle band heater ensures that the molten plastic material remains in its ideal state for efficient molding. This is crucial for achieving high-quality and consistent results in the production process. Without a reliable nozzle band heater, the risk of defects and inconsistencies in the final product increases significantly.

Features and specifications of the nozzle band heater 50×50 in Pakistan

The nozzle band heater 50×50 in Pakistan comes with a range of features and specifications that make it an ideal choice for injection molding machines. These heaters are typically made from high-quality materials such as stainless steel and have a power rating that allows for fast and efficient heating.

The 50×50 variant is designed to fit perfectly around standard nozzle sizes, ensuring a snug fit and optimal heat transfer. These band heaters usually have a maximum operating temperature of around 500 degrees Celsius, which is more than sufficient for most injection molding applications.

Another important feature of the nozzle band heater 50×50 in Pakistan is its ability to distribute heat evenly along the length of the nozzle. This ensures that the molten plastic material is heated uniformly, reducing the risk of overheating or underheating in certain areas.

Benefits of using a high-quality nozzle band heater in injection molding machines

Investing in a high-quality nozzle band heater, such as the 50×50 variant, for your injection molding machine in Pakistan can offer several significant benefits. Firstly, these heaters provide precise temperature control, allowing you to maintain the optimal temperature for your specific molding requirements. This leads to improved product quality and consistency.

Secondly, a reliable nozzle band heater ensures faster heat-up and response times, increasing the overall efficiency of the injection molding process. With quicker heating, you can reduce production cycle times, ultimately leading to higher productivity and cost savings.

Additionally, the use of a high-quality nozzle band heater can help prolong the lifespan of your injection molding machine. By maintaining a consistent temperature and preventing thermal shocks, these heaters reduce the strain on the machine’s components, minimizing the risk of premature wear and tear.

Installation and maintenance tips for the nozzle band heater 50×50 in Pakistan

Installing and maintaining the Nozzle Band Heater Injection Molding Machine Heater 50×50 is relatively straightforward, but it is essential to follow the manufacturer’s instructions for optimal performance and safety.

- Installation: Before installing the nozzle band heater, ensure that the nozzle is clean and free from any debris or contaminants. Then, place the band heater around the nozzle, making sure it fits snugly. Secure it in place using the provided clamps or screws, ensuring even pressure distribution.

- Electrical connections: Any loose connections can lead to poor performance or electrical hazards. If necessary, consult an electrician or a professional technician for assistance.

- Regular maintenance: Periodically inspect the nozzle band heater for any signs of damage or wear. Check for loose connections, frayed wires, or any abnormal heating patterns. Clean the heater regularly to remove any accumulated dirt or debris that may affect its performance.

If you are unsure about any aspect of the installation or maintenance process, it is best to seek professional help.

Common issues and troubleshooting solutions for the nozzle band heater

Like any mechanical component, nozzle band heaters can encounter issues over time.

- Uneven heating: If you notice that the nozzle is not heating evenly, it could indicate a problem with the band heater. Check for any loose connections, damaged wires, or uneven pressure distribution. Adjust the clamps or screws to ensure a snug fit and even heat transfer.

- Overheating: If the nozzle band heater is overheating, it could be due to a faulty thermostat or insufficient insulation. Check the thermostat settings and replace it if necessary. Ensure that the insulation is intact and providing adequate protection against heat loss.

- Insufficient heating: If the nozzle is not reaching the desired temperature, it may be due to a damaged or worn-out band heater. Also, check the electrical connections to ensure they are secure and providing sufficient power.

If you encounter any other issues or are unsure about the troubleshooting process, it is best to consult a professional technician or the manufacturer for assistance.

Cost considerations and budgeting for the nozzle band heater

When budgeting for a nozzle band heater for your injection molding machine, it is important to consider both the initial cost and the long-term value. While it may be tempting to opt for the cheapest option available, compromising on quality can result in frequent breakdowns, reduced productivity, and increased maintenance costs.

Instead, focus on finding a balance between affordability and quality. Look for suppliers who offer competitive pricing without compromising on the durability and performance of the nozzle band heater. Consider the warranty and after-sales support offered by the supplier, as these factors contribute to the overall value of your investment.

Making the right choice for your injection molding machine heating needs

The Nozzle Band Heater Injection Molding Machine Heater 50×50 plays a critical role in maintaining the optimal temperature for efficient and high-quality production. By understanding the importance of these heaters, their features and specifications, and the benefits they offer, you can make an informed decision for your injection molding machine.

Remember to follow the installation and maintenance tips provided to ensure safe and reliable operation. In case of any issues, troubleshoot with the help of the suggested solutions or seek professional assistance.

| Weight | 0.5 kg |

|---|

1 review for Nozzle Band Heater Injection Molding Machine Heater 50×50 in Pakistan

Add a review Cancel reply

You must be logged in to post a review.

Related products

Machine Heaters pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 45×35 in Pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan

Machine Heaters pakistan

Thermal Silicon Grease SSR Relay Heat Sink Paste Injection in pakistan

Machine Heaters pakistan

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

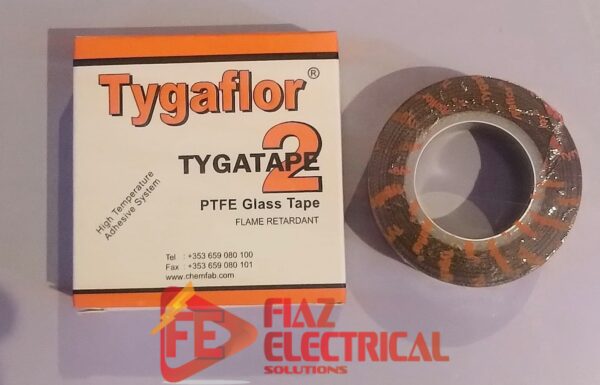

Tygaflor PTFE Glass Tape Original Width 1/2” 3/4″ 1” Length 10 Meter Pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting