Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan

₨ 775.0

- Introducing the Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan.

- This powerful heating solution is designed to meet the demands of your injection molding machine.

- With its efficient heating capabilities, it ensures precise temperature control, resulting in consistent and high-quality output.

- Crafted with durability in mind, this heater is built to withstand the rigors of industrial use.

- Its sturdy construction guarantees long-lasting performance, while its compact size allows for easy installation and space-saving.

- Featuring advanced technology, this band heater distributes heat evenly across the nozzle, eliminating hotspots and ensuring uniform heating.

Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan

As an entrepreneur in the injection molding industry, one of the crucial decisions you have to make is choosing the right nozzle band heater for your injection molding machine. The efficiency and effectiveness of your machine depend heavily on the heater you select. In Pakistan, where the manufacturing sector is flourishing, it is essential to find the best nozzle band heater for your business. In this article, I will guide you through the process of choosing the best Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan.

Importance of choosing the right heater for your injection molding machine

Choosing the right Nozzle Band Heater Injection Molding Machine Heater 35×35 is crucial for the smooth operation of your injection molding machine. The heater plays a vital role in maintaining the desired temperature of the molten plastic, ensuring proper flow and solidification. A poorly chosen heater can lead to various issues, including inconsistent product quality, longer cycle times, and even damage to the machine.

By investing in a high-quality nozzle band heater, you can optimize your production process and achieve better results. The right heater will provide efficient heat transfer, uniform temperature distribution, and precise control. It will also contribute to energy savings and reduce downtime due to maintenance or heater failures.

Factors to consider when selecting a nozzle band heater

When selecting a nozzle band heater for your injection molding machine, several factors need to be considered. These factors will help you determine the most suitable heater for your specific requirements

- Temperature Range: Consider the range of temperatures your application requires. Ensure that the heater you choose can operate within that range without compromising performance or safety.

- Power Density: Power density refers to the amount of power output per unit area of the heater. Higher power density heaters can heat up faster, but they may also have a shorter lifespan. Evaluate your production needs and select a heater with an appropriate power density.

- Construction and Material: The construction and material of the heater play a crucial role in its durability and performance. Look for heaters made from high-quality materials that can withstand the harsh conditions of injection molding.

- Installation and Maintenance: Consider the ease of installation and maintenance of the heater. Look for heaters that are easy to install, remove, and clean. Accessible terminals and insulation can make a significant difference in the convenience of maintenance.

- Safety Features: Safety should always be a top priority. Choose heaters with built-in safety features such as thermal cut-offs, grounded shields, and proper insulation to prevent accidents and protect your employees.

Understanding the specifications of a 35×35 heater

A nozzle band heater with a specification of 35×35 refers to its dimensions. The first number represents the inner diameter (35 mm), while the second number represents the height or width of the heater (35 mm). Understanding the specifications of a 35×35 heater is essential as it determines whether it will fit your machine’s nozzle properly.

Before purchasing a 35×35 heater, measure the dimensions of your machine’s nozzle to ensure a snug fit. An ill-fitting heater can lead to inefficient heat transfer and potential damage to the machine. Additionally, check the wattage and voltage specifications of the heater to ensure compatibility with your power supply.

Types of nozzle band heaters available in Pakistan

In Pakistan, there are several types of nozzle band heaters available in the market. Here are some common types of nozzle band heaters:

- Ceramic Band Heaters: Ceramic band heaters are known for their high thermal efficiency and durability. They provide excellent heat transfer and uniform temperature distribution. These heaters are ideal for high-temperature applications and can withstand extreme operating conditions.

- Mica Band Heaters: Mica band heaters are cost-effective and provide efficient heat transfer. They are lightweight and have a quick response time. Mica band heaters are suitable for low to medium-temperature applications.

- Mineral Insulated Band Heaters: Mineral insulated band heaters are highly robust and can withstand high temperatures. They offer excellent heat transfer and uniform heating. These heaters are suitable for applications that require high watt densities and precise temperature control.

- Finned Band Heaters: Finned band heaters have extended surfaces (fins) that increase the heat transfer area. They are suitable for applications that require a higher watt density and faster heat-up times. Finned band heaters are commonly used in extrusion and blow molding processes.

Comparison of different brands and models

When choosing a Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan, it is essential to compare different brands and models to make an informed decision. Here are some factors to consider during the comparison process:

- Quality and Durability: Look for heaters made from high-quality materials that can withstand the demanding conditions of injection molding. Consider the warranty offered by the manufacturer as an indicator of their confidence in the product’s durability.

- Customization Options: Consider whether the brand offers customization options to meet your specific requirements. Some manufacturers provide the flexibility to choose watt densities, voltage ratings, and other specifications to tailor the heater to your needs.

- Price and Value: Compare the prices of different brands and models, taking into account the features, quality, and durability they offer. Look for a balance between affordability and value for money.

- Customer Support: Evaluate the customer support provided by the brand. A responsive and knowledgeable customer support team can be invaluable in case of any issues or queries regarding the heater.

Tips for maintaining and troubleshooting your heater

To ensure the longevity and optimal performance of your nozzle band heater injection molding machine heater 35×35, regular maintenance and troubleshooting are essential. Here are some tips to help you maintain and troubleshoot your heater effectively:

- Clean Regularly: Clean the heater regularly to remove any accumulated debris or plastic residue. Use a soft brush or compressed air to clean the surface and ensure efficient heat transfer.

- Inspect for Damage: Regularly inspect the heater for any signs of damage such as cracks or frayed wires. Replace damaged heaters immediately to prevent further issues.

- Check Connections: Check the electrical connections of the heater regularly to ensure they are secure. Loose connections can cause overheating or failure of the heater.

- Monitor Temperature: Monitor the temperature of the heater during operation to ensure it stays within the desired range. Use a reliable temperature monitoring device for accurate readings.

- Consult Manufacturer’s Guidelines: Refer to the manufacturer’s guidelines for specific maintenance instructions and troubleshooting tips. Following these guidelines will help you maximize the lifespan and performance of your heater.

Conclusion and final thoughts

Choosing the best nozzle band heater injection molding machine heater 35×35 requires careful consideration of various factors such as temperature range, power density, construction, and safety features. Understanding the specifications of a 35×35 heater is crucial to ensure a proper fit. Comparing different brands and models, considering their reputation, quality, and price, will help you make an informed decision

| Weight | 0.5 kg |

|---|

1 review for Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan

Add a review Cancel reply

You must be logged in to post a review.

Related products

Machine Heaters pakistan

Machine Heaters pakistan

Machine Heaters pakistan

Machine Heaters pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 40×60 in Pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan

Machine Heaters pakistan

Cables, Wires and accessories Pakistan

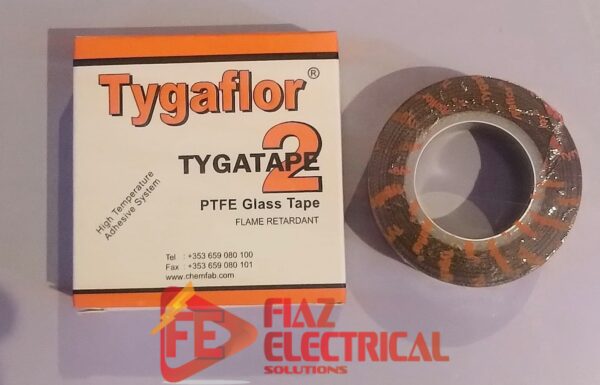

Tygaflor PTFE Glass Tape Original Width 1/2” 3/4″ 1” Length 10 Meter Pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 50×33 in Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting