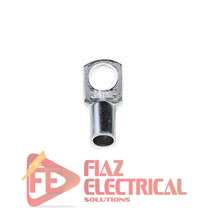

Cable Joint Sleeve Copper 16mm in Pakistan

₨ 21.0

- Introducing the Cable Joint Sleeve Copper 16mm in Pakistan, the perfect solution for all your electrical needs. This high-quality copper joint sleeve ensures secure and reliable connections for your cables.

- Designed with precision, it offers exceptional conductivity, reducing power loss and ensuring efficient electrical flow.

- Crafted with durability in mind, this copper joint sleeve is built to withstand the harshest conditions, providing long-lasting performance and peace of mind.

- Whether you’re working on a commercial project or a DIY home improvement task, the Cable Joint Sleeve Copper 16mm in Pakistan delivers unmatched quality and reliability.

- Experience seamless connectivity and enjoy an uninterrupted power supply with this essential electrical accessory. Don’t settle for subpar connections – choose the Cable Joint Sleeve Copper 16mm in Pakistan and elevate your electrical installations to new heights.

Cable Joint Sleeve Copper 16mm in Pakistan

When it comes to electrical projects, safety and reliability are of utmost importance. One crucial component that plays a significant role in ensuring the smooth functioning of electrical systems is the cable joint sleeve. In Pakistan, the Cable Joint Sleeve Copper 16mm is widely recognized for its exceptional performance and numerous benefits. This article aims to shed light on the advantages of using Cable Joint Sleeve Copper 16mm in Pakistan, its role in enhancing electrical safety, factors to consider when selecting this material, the installation process, maintenance tips, a comparison with other materials, and finally, concluding thoughts on its benefits.

Understanding the Importance of Cable Joint Sleeves in Electrical Projects

Before delving into the benefits of using Cable Joint Sleeve Copper 16mm, it is crucial to understand the importance of cable joint sleeves in electrical projects. Cable joint sleeves connect and protect electrical cables, ensuring a secure and reliable connection. They provide insulation, mechanical support, and protection against environmental factors such as moisture, dust, and heat. Moreover, cable joint sleeves also prevent the spread of fire in case of a short circuit, making them a critical component in maintaining electrical safety.

Benefits of Using Cable Joint Sleeve Copper 16mm in Pakistan

Now let’s explore the specific advantages of using Cable Joint Sleeve Copper 16mm in Pakistan. Firstly, copper is a highly conductive material, allowing for efficient transmission of electrical current. This ensures minimal power loss and enhances the overall performance of electrical systems. Additionally, copper has excellent corrosion resistance, making it suitable for various environmental conditions. In Pakistan, where humidity and extreme temperatures are common, using Cable Joint Sleeve Copper 16mm ensures durability and longevity.

Furthermore, copper is known for its high thermal conductivity. This means that Cable Joint Sleeve Copper 16mm can efficiently dissipate heat generated during electrical operations, preventing overheating and potential damage to cables. Moreover, the malleability of copper makes it easy to work with during the installation process, reducing the risk of cable damage.

How Cable Joint Sleeve Copper 16mm Enhances Electrical Safety

Electrical safety should always be a top priority in any project. Cable Joint Sleeve Copper 16mm in Pakistan significantly contributes to enhancing electrical safety. Firstly, the excellent insulation properties of copper prevent electrical leakage, reducing the risk of electrical shocks and short circuits. This is particularly crucial in high-voltage applications where the consequences of a fault can be catastrophic.

Additionally, the use of Cable Joint Sleeve Copper 16mm ensures proper grounding, further enhancing safety. Proper grounding helps in diverting excess electrical current to the ground, preventing equipment damage and reducing the risk of electrical fires. The combination of efficient insulation and grounding provided by Cable Joint Sleeve Copper 16mm makes it an ideal choice for electrical projects.

Factors to Consider When Selecting Cable Joint Sleeve Copper 16mm

Selecting the right Cable Joint Sleeve Copper 16mm for your electrical projects in Pakistan requires careful consideration of various factors. Firstly, it is essential to determine the required size and specifications based on the cable diameter and voltage requirements. Choosing the correct size ensures a secure and reliable connection. Additionally, considering the environmental conditions, such as temperature and moisture, is crucial to ensure the longevity and performance of the cable joint sleeve.

Another factor to consider is the type of cable insulation. Compatibility between the cable insulation and the joint sleeve material is essential to maintain optimal performance and prevent any chemical reactions or degradation. Lastly, it is essential to source cable joint sleeves from reputable manufacturers or suppliers to ensure quality and reliability.

Installation Process of Cable Joint Sleeve Copper 16mm

The Cable Joint Sleeve Copper 16mm installation process in Pakistan can be divided into several steps. Firstly, the cables to be joined should be prepared by cleaning and removing any dirt or moisture. This ensures a proper connection and optimal performance. Next, the cable joint sleeve is fitted onto the cables and secured using clamps or connectors.

Once the joint sleeve is in place, the cables are inserted into the sleeve, ensuring proper alignment and tightness. It is crucial to follow the manufacturer’s instructions regarding the tightening torque to prevent over-tightening or under-tightening. Finally, the joint is sealed using insulating tapes or heat-shrinkable sleeves to provide complete protection against moisture, dust, and other environmental factors.

Maintenance and Care Tips for Cable Joint Sleeve Copper 16mm

To ensure the longevity and optimal performance of Cable Joint Sleeve Copper 16mm, proper maintenance and care are essential. Regular inspection of the joint sleeves is necessary to identify any signs of damage, such as cracks or corrosion. Any damaged joint sleeves should be replaced immediately to prevent any compromise in electrical safety.

Furthermore, periodic cleaning of the joint sleeves using a soft cloth and mild detergent can help remove any dirt or debris that may accumulate over time. It is crucial to avoid using abrasive materials or harsh chemicals that could damage the copper surface. Additionally, maintaining proper environmental conditions, such as temperature and humidity, can further extend the lifespan of the joint sleeves.

Comparison of Cable Joint Sleeve Copper 16mm with Other Materials

While Cable Joint Sleeve Copper 16mm offers numerous benefits for electrical projects in Pakistan, it is essential to consider other materials for comparison. One common alternative is aluminum joint sleeves. While aluminum is a cost-effective option, it has lower conductivity compared to copper. This can result in higher power losses and reduced performance in electrical systems. Additionally, aluminum is more prone to corrosion, making it less suitable for environments with high humidity or corrosive elements.

Another alternative is polymer-based joint sleeves. These sleeves offer good insulation properties and are lightweight, making them easier to handle during installation. However, they may not provide the same level of conductivity and heat dissipation as copper. Additionally, polymer-based sleeves may be less durable and more susceptible to environmental factors such as UV radiation.

Conclusion and Final Thoughts on the Benefits of Cable Joint Sleeve Copper 16mm

Cable Joint Sleeve Copper 16mm offers numerous benefits for electrical projects. Its high conductivity, corrosion resistance, and thermal properties make it an ideal choice for ensuring efficient and safe electrical systems. When selecting Cable Joint Sleeve Copper 16mm, factors such as size, compatibility, and sourcing from reputable manufacturers should be considered. The installation process should follow manufacturer guidelines, and regular maintenance is crucial for optimal performance. While alternative materials exist, the unique properties of Cable Joint Sleeve Copper 16mm make it a top choice for electrical projects in Pakistan.

| Weight | 0.5 kg |

|---|

1 review for Cable Joint Sleeve Copper 16mm in Pakistan

Add a review Cancel reply

You must be logged in to post a review.

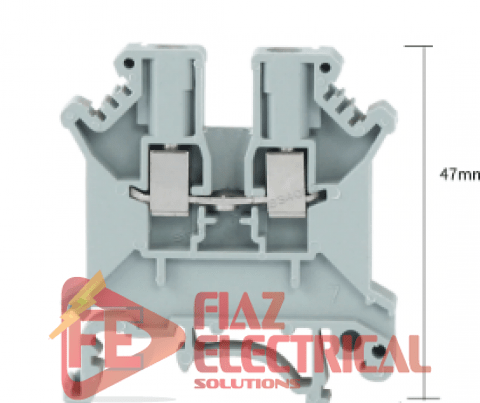

Related products

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

PVC Insulated 1 Core (23/76) Flexible Copper Electric Wire Roll 90 Meter (Red)

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

Cables, Wires and accessories Pakistan

PVC Insulated 1 Core (23/76) Flexible Copper Electric Wire Roll 90 Meter (Green)

Cables, Wires and accessories Pakistan

Insulated Thimbles Tubeless bootless 0.75mm Red 100pc in Pakistan

Cables, Wires and accessories Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting