Proximity Sensors 12mm AC NO In Pakistan

₨ 500.00

Sensors 12mm AC NO

Product Name: Inductive Proximity Sensor Switch

Wire Type: AC 2 Wire (Brown, Blue)

Switch Appearance Type: Cylinder Type

Supply Voltage: AC 90-220V

Current Output: 300mA

Detect Object: Iron

Output Type: PNP NO (normally open)

Diameter of Column Sensor: 12mm Diameter

Detecting Distance: 4mm

Cable Length: 1.2m (Approx)

External Material: Plastic, Alloy

Condition: 100% brand new

Proximity Sensors

Proximity Sensors 12mm AC NO In Pakistan work based on different principles, including capacitive, inductive, magnetic, and photoelectric. Each type of proximity sensor has its own unique advantages and applications. By understanding the different types and their functionalities, businesses in Pakistan can make informed decisions about which proximity sensor to use for their specific needs.

In today’s fast-paced industrial landscape, efficiency and precision are crucial for success. To achieve optimal performance, businesses are increasingly turning to advanced technologies. One such technology that has revolutionized the industrial sector is proximity sensors.

Understanding the different types of proximity sensors

- Capacitive Proximity Sensors: They are ideal for detecting non-metallic objects and are commonly used in industries such as food processing, packaging, and textiles.

- Inductive Proximity Sensors: Inductive sensors rely on the principle of electromagnetic induction to detect metallic objects. They are widely used in automation processes, robotics, and assembly lines.

- Magnetic Proximity Sensors: Magnetic sensors use magnetic fields to detect the presence of metallic objects. They are commonly used in manufacturing plants, automotive industries, and security systems.

- Photoelectric Proximity Sensors: Photoelectric sensors use light beams to detect objects. They are highly versatile and can be used in various applications, such as object detection, sorting, and counting.

By carefully evaluating the specific requirements of their industrial processes, businesses in Pakistan can choose the most suitable type of proximity sensor to enhance efficiency and precision.

Advantages of using proximity sensors in industrial applications

The integration of Proximity Sensors 12mm AC NO in industrial applications offers numerous advantages. Firstly, these sensors eliminate the need for physical contact, making them highly reliable and durable. They can withstand harsh environmental conditions, such as extreme temperatures, vibrations, and moisture, without compromising their accuracy.

Additionally, Proximity Sensors 12mm AC NO In Pakistan provide real-time data, allowing businesses to monitor and optimize their operations. This real-time feedback enhances efficiency and reduces downtime by alerting operators to any potential issues or malfunctions. By identifying and rectifying problems promptly, businesses can minimize costly disruptions and improve overall productivity.

Furthermore, proximity sensors contribute to workplace safety by detecting potential hazards. For example, in automated manufacturing plants, proximity sensors can prevent collisions between machinery and human operators, reducing the risk of accidents and injuries. This not only protects employees but also safeguards expensive equipment from damage.

Features and specifications of 12mm AC NO proximity sensors

When it comes to proximity sensors, the 12mm AC NO model stands out for its exceptional performance and reliability. The Proximity Sensors 12mm AC NO In Pakistan operate on alternating current and normally open (NO) configuration. They can detect objects within a range of 12mm, providing ample distance for various industrial processes. They are resistant to electromagnetic interference, vibrations, and temperature variations, guaranteeing consistent and accurate results. Additionally, the 12mm AC NO proximity sensors have a long service life, reducing maintenance and replacement costs.

Choose the right proximity sensor for your specific needs

Selecting the right proximity sensor for your specific needs requires careful consideration of various factors.

- Sensing Range: Consider the specific requirements of your application and choose a sensor with an appropriate range.

- Output Type: Different proximity sensors have different output types, such as analog, digital, or frequency. Understand the compatibility of the output type with your existing systems and select accordingly.

- Mounting Options: Consider the available space and mounting options in your industrial setup. Choose a proximity sensor that can be easily and securely mounted in the desired location.

- Cost-Effectiveness: Evaluate the overall cost-effectiveness of the proximity sensor, considering factors such as initial investment, maintenance requirements, and expected lifespan. Opt for a sensor that offers a balance between performance and cost.

By carefully evaluating these factors and consulting with experts, businesses in Pakistan can choose the right proximity sensor to enhance their efficiency and precision.

Installation and maintenance tips for 12mm AC NO proximity sensors

Proper installation and regular maintenance are essential for ensuring optimal performance and longevity of 12mm AC NO proximity sensors.

- Installation: Follow the manufacturer’s guidelines for proper installation of the proximity sensor.

- Calibration: If required, calibrate the proximity sensor according to the specific requirements of your application. This will ensure precise and consistent performance.

- Cleaning: Regularly clean the sensor to remove any dust, debris, or contaminants that may affect its functionality. Use non-abrasive cleaning agents and avoid direct contact with the sensing surface.

- Periodic Inspection: Conduct regular inspections to identify any signs of wear, damage, or loose connections. Promptly address any issues to prevent further damage and ensure uninterrupted operation.

- Training and Awareness: Provide training to the operators and maintenance personnel regarding the proper use and care of proximity sensors. This will help prevent accidental damage and promote efficient operation.

By following these installation and maintenance tips, businesses can maximize the performance and longevity of their 12mm AC NO proximity sensors, ultimately improving efficiency and precision in their industrial processes.

The benefits of using 12mm AC NO proximity sensors in improving efficiency and precision in industrial settings

Proximity Sensors, particularly the 12mm AC NO model, offer numerous advantages for businesses in Pakistan. These sensors enhance efficiency and precision by providing accurate and real-time detection of objects without physical contact. They contribute to workplace safety, reduce downtime, and optimize industrial processes.

By understanding the different types of proximity sensors and their applications, businesses can choose the most suitable sensor for their specific needs. The Proximity Sensors 12mm AC NO, with their exceptional features and specifications, are ideal for a wide range of applications in Pakistan.

Sensors 12mm AC NO

- Inductive Proximity Sensors PNP NO(normally open) 90-220v AC 12mm are widely used in industrial control automation for detection, control, and non-contact switching.

- When the proximity switch is closed, some target objects will send control signals.

- Widely used in the machine, paper, light industry, limited station, orientation, photographic counting, speeding trial etc.

- It is very easy to install and also for it,s long range of supply voltage (90-220v AC).

| Weight | .2 kg |

|---|

1 review for Proximity Sensors 12mm AC NO In Pakistan

Add a review Cancel reply

You must be logged in to post a review.

Related products

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

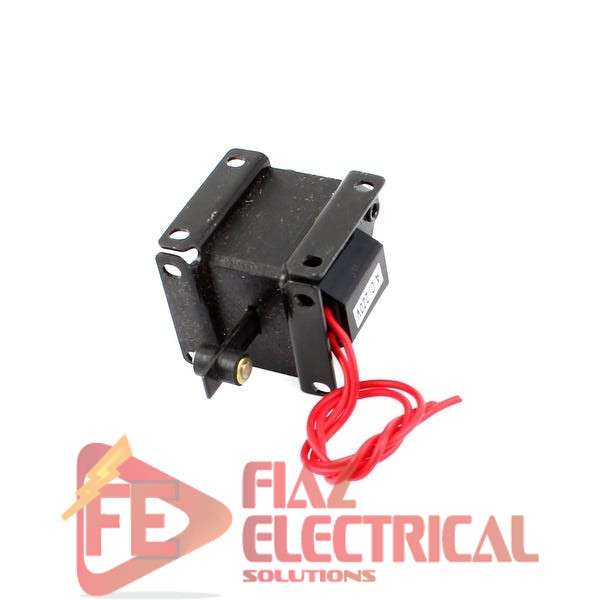

Tractive Magnet Solenoid Electromagnet SA-2402 AC weight plunger Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Thermocouple K-type Thread M8 Screw Probe 2 Meter Shield Wire near 2.5 Sooter in Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

MI Limit Switch Adjustable/Rotatable Roller Arm Type Mi-8108

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

LED Light Push Button Switch LA38 203 22mm Green Tiktik in Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Thermocouple K-type Thread M6 Screw Probe near 2 Sooter in Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Tractive Magnet Solenoid Electromagnet SA-2502 Ac weight plunger Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Omron Incremental Rotary Encoder E6B2-CWZ6C 360P/R in Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting