Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan

₨ 750.00

- Introducing the Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan, a game-changer for your injection molding needs.

- Crafted with precision and efficiency in mind, this heater is designed to deliver exceptional performance.

- With its advanced technology, this nozzle band heater ensures uniform heat distribution, enabling optimal molding results every time

- Its robust construction guarantees durability, while the adjustable temperature control allows for precise heat management.

- Say goodbye to inconsistent output and hello to enhanced productivity.

- Designed specifically for the injection molding industry, this heater is a must-have for manufacturers who prioritize quality and efficiency.

Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan

As an experienced professional in the field of injection molding, I have always been on the lookout for ways to maximize efficiency and optimize the production process. One product that has caught my attention is the Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan. This innovative heater is designed to provide efficient heating for injection molding machines, specifically the nozzle area. Its compact size and powerful performance make it an ideal choice for manufacturers in Pakistan.

Benefits of using Nozzle Band Heater Injection Molding Machine Heater 40×40

Utilizing the Nozzle Band Heater Injection Molding Machine Heater 40×40 offers numerous benefits for manufacturers. Firstly, it ensures precise and uniform heating of the nozzle, resulting in consistent molding quality. This translates to higher productivity and reduced wastage. Additionally, the heater’s fast heat-up time allows for quicker start-up and reduced downtime, ultimately increasing overall production efficiency.

Furthermore, the Nozzle Band Heater Injection Molding Machine Heater 40×40 is designed with energy efficiency in mind. Its advanced insulation materials and optimized heating elements minimize heat loss, resulting in lower energy consumption.

Features and specifications of Nozzle Band Heater Injection Molding Machine Heater 40×40

The Nozzle Band Heater Injection Molding Machine Heater 40×40 boasts a range of impressive features and specifications. Its compact size of 40x40mm allows for easy installation and ensures a snug fit around the nozzle. The heater is constructed using high-quality materials that are resistant to wear and tear, ensuring longevity and durability.

With adjustable temperature settings, the Nozzle Band Heater Injection Molding Machine Heater 40×40 provides flexibility for different molding requirements. The heater is equipped with a reliable and accurate temperature control system, allowing precise temperature regulation to meet the specific needs of the production process.

How to install Nozzle Band Heater Injection Molding Machine Heater 40×40

Installing the Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan is a straightforward process. Begin by ensuring that the power to the machine is turned off and unplugged. Carefully remove any existing heaters from the nozzle area. Next, position the Nozzle Band Heater Injection Molding Machine Heater 40×40 around the nozzle and secure it in place using the provided clamps. Ensure that the heater is snugly fitted to prevent any heat loss. Finally, connect the power supply and turn on the machine. The heater is now ready for operation.

Maintenance tips for Nozzle Band Heater Injection Molding Machine Heater 40×40

To ensure the optimal performance and longevity of the Nozzle Band Heater Injection Molding Machine Heater 40×40, regular maintenance is essential.

- Regularly clean the surface of the heater to remove any dust or debris that may accumulate.

- Inspect the heater for any signs of damage, such as cracks or frayed wires. Replace any damaged parts immediately.

- Check the temperature control system regularly to ensure accurate temperature regulation.

- If the heater is not in use for an extended period, it is recommended to disconnect the power supply to prevent unnecessary energy consumption.

- Seek professional assistance for any major repairs or technical issues.

Customer reviews and testimonials of Nozzle Band Heater Injection Molding Machine Heater 40×40

The Nozzle Band Heater Injection Molding Machine Heater 40×40 has received positive feedback from customers in Pakistan. Many users have praised its efficiency, durability, and ease of installation. They have also highlighted the improved molding quality and energy-saving benefits that this heater provides. It is always beneficial to read customer reviews and testimonials before making a purchase decision, as they offer valuable insights and firsthand experiences.

Comparison of Nozzle Band Heater Injection Molding Machine Heater 40×40 with other similar products

When considering the Nozzle Band Heater Injection Molding Machine Heater 40×40, it is crucial to compare it with other similar products on the market. Factors such as performance, durability, energy efficiency, and price should be taken into account. Conducting a thorough comparison will help manufacturers make an informed decision and choose the product that best suits their specific requirements.

Understanding the importance of efficient heating in injection molding machines

Efficient heating plays a crucial role in the injection molding process. It directly impacts the quality of the molded products and the overall productivity of the manufacturing operation. Properly heated nozzles ensure uniform material flow, preventing defects such as air pockets or inconsistent fillings. This, in turn, reduces the need for rework and increases the yield of high-quality finished products.

Moreover, efficient heating contributes to shorter cycle times, allowing for faster production and increased output. This is particularly important in high-volume manufacturing environments where time is of the essence. By investing in the Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan, manufacturers can achieve improved efficiency and maximize their operational capabilities.

Final thoughts on Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan

The Nozzle Band Heater Injection Molding Machine Heater 40×40 offers an effective solution for manufacturers in Pakistan seeking to maximize efficiency and optimize their injection molding processes. Its compact size, energy efficiency, and precise temperature control make it a valuable addition to any production line. By investing in this innovative heater, manufacturers can ensure consistent molding quality, expedite production cycles, and reduce operating costs. With its numerous benefits and positive customer reviews, the Nozzle Band Heater Injection Molding Machine Heater 40×40 is a reliable choice for manufacturers looking to enhance their productivity and stay ahead in the competitive market.

| Weight | 0.5 kg |

|---|

1 review for Nozzle Band Heater Injection Molding Machine Heater 40×40 in Pakistan

Add a review Cancel reply

You must be logged in to post a review.

Related products

Cables, Wires and accessories Pakistan

Machine Heaters pakistan

Thermal Silicon Grease SSR Relay Heat Sink Paste Injection in pakistan

Machine Heaters pakistan

Machine Heaters pakistan

Machine Heaters pakistan

Machine Heaters pakistan

Cables, Wires and accessories Pakistan

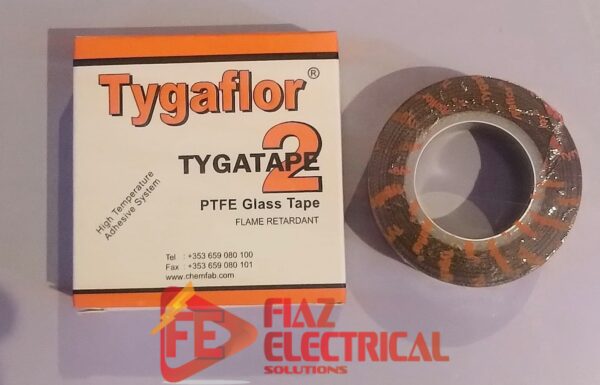

Tygaflor PTFE Glass Tape Original Width 1/2” 3/4″ 1” Length 10 Meter Pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 35×35 in Pakistan

Machine Heaters pakistan

Nozzle Band Heater Injection Molding Machine Heater 40×60 in Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting