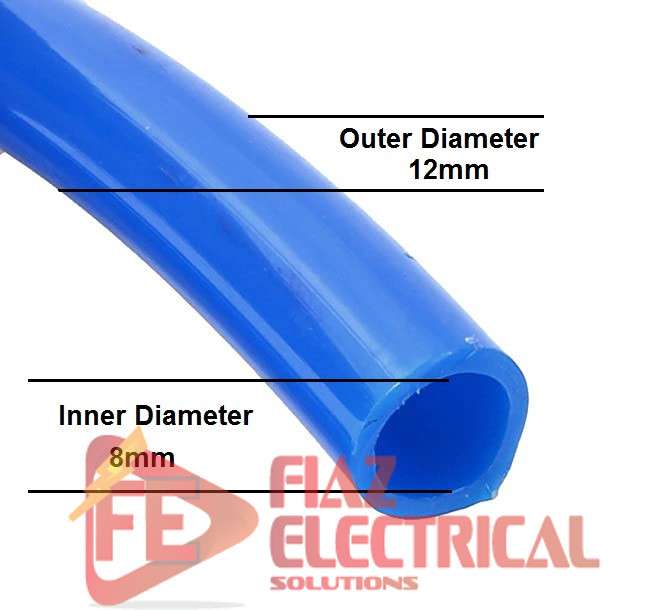

Pneumatic Pipe 12mm Per Foot in Pakistan

₨ 45.00

- Pneumatic Pipe 12mm Per Foot in Pakistan. Designed with precision and reliability in mind, this versatile pipe is a must-have for any pneumatic system.

- This 12mm pneumatic pipe is perfect for a wide range of applications, offering seamless airflow and efficient operation.

- Whether you’re looking to connect air tools or build a pneumatic circuit, this pipe delivers exceptional results.

- With its flexible design, this pipe can easily be cut to the desired length, making installation a breeze.

- Invest in the Pneumatic Pipe 12mm Per Foot in Pakistan and experience enhanced productivity and efficiency in your pneumatic systems. Don’t settle for subpar performance – choose quality that lasts.

Pneumatic Pipes

Pneumatic pipes play a crucial role in various industries, especially in the field of automation and manufacturing. These pipes are used to transport compressed air or other gases from one place to another, enabling the operation of pneumatic systems. If you are in Pakistan and looking for the right pneumatic pipe for your needs, understanding the 12mm per foot measurement is essential. In this comprehensive guide, I will walk you through everything you need to know about pneumatic pipes, with a specific focus on the Pneumatic Pipe 12mm Per Foot in Pakistan.

Understanding the 12mm per Foot Measurement

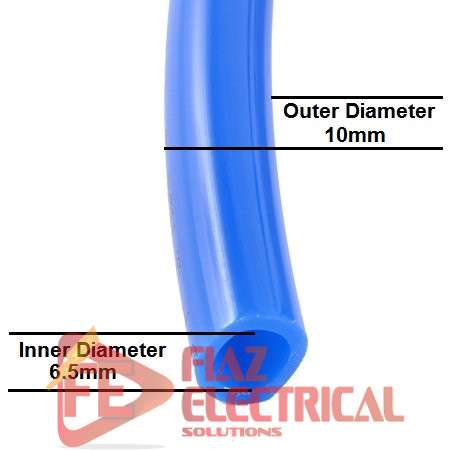

The Pneumatic Pipe 12mm Per Foot in Pakistan measurement refers to the diameter of the pneumatic pipe. In Pakistan, this measurement is widely used and ensures compatibility with various pneumatic systems. The 12mm diameter provides a balance between airflow and pressure, making it suitable for a wide range of applications. Whether you are setting up a pneumatic system for industrial automation or simply need to transport compressed air in your workshop, the 12mm per foot pneumatic pipe is a versatile choice.

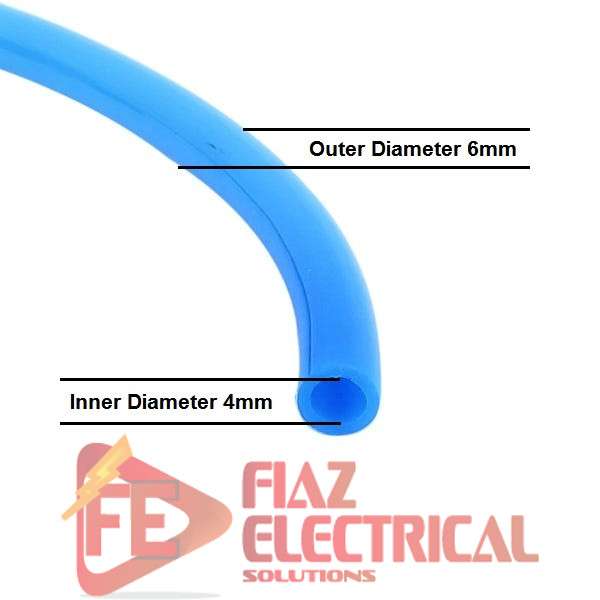

Types of Pneumatic Pipes Available in Pakistan

In Pakistan, you will find a variety of pneumatic pipes available in the market. These pipes can be categorized based on their material composition, flexibility, and pressure rating. The most common types of pneumatic pipes include:

- Polyurethane Pneumatic Pipes: These pipes are known for their excellent flexibility and resistance to abrasion. They are ideal for applications that require frequent bending and twisting.

- Nylon Pneumatic Pipes: Nylon pipes are lightweight, durable, and have a high resistance to chemicals and oils. They are commonly used in industries where there is a need for corrosion resistance.

- PVC Pneumatic Pipes: PVC pipes are cost-effective and easy to install. They have good resistance to corrosion and can handle moderate pressure levels.

- Rubber Pneumatic Pipes: Rubber pipes are known for their excellent flexibility and resistance to extreme temperatures. They are commonly used in applications that involve outdoor or harsh environments.

Advantages of Using Pneumatic Pipes for Various Applications

Using Pneumatic Pipe 12mm Per Foot in Pakistan for your applications in Pakistan offers several advantages. Some of the key benefits include:

- Safety: Pneumatic pipes are safer to use compared to electrical systems, as they do not carry the risk of electrical shocks or sparks. This makes them suitable for industries where safety is a top priority.

- Efficiency: Pneumatic systems are highly efficient, enabling precise control and quick response times. The use of pneumatic pipes ensures a consistent supply of compressed air, allowing machines to operate at their optimal performance levels.

- Cost-Effective: Pneumatic pipes are generally more cost-effective than other types of piping systems.

- Versatility: Pneumatic pipes can be used in a wide range of applications, from simple workshop setups to complex industrial automation systems. They can handle various pressures and temperatures, making them suitable for diverse environments.

Factors to Consider When Choosing Pneumatic Pipes

When selecting pneumatic pipes for your needs in Pakistan, there are several factors you should consider:

- Pressure Rating: Ensure that the pneumatic pipes you choose can handle the required pressure levels in your application. Higher pressure ratings are necessary for demanding industrial settings.

- Temperature Range: Consider the temperature range in which the pneumatic pipes will be operating. Some pipes can withstand extreme temperatures, while others may become brittle or lose flexibility.

- Chemical Compatibility: If your application involves exposure to chemicals or oils, choose pneumatic pipes that are resistant to the specific substances present. This will prevent damage and ensure the longevity of the pipes.

- Flexibility: Depending on the layout and design of your system, you may require flexible pneumatic pipes. Consider the bending radius and flexibility of the pipes to ensure they can be easily routed without causing any restrictions.

Installation and Maintenance of Pneumatic Pipes

Proper installation and maintenance are crucial for the optimal performance and longevity of pneumatic pipes.

- Installation: Follow the manufacturer’s guidelines for installing the pneumatic pipes. Ensure that the pipes are properly supported, avoiding excessive strain or tension. Use the appropriate fittings and connectors for a secure and leak-free connection.

- Regular Inspections: Periodically inspect the pneumatic pipes for signs of wear, damage, or leaks. Replace any damaged or worn-out sections promptly to prevent system failures.

- Cleaning and Lubrication: Clean the pneumatic pipes regularly to remove any dust, debris, or contaminants. Additionally, lubricate the fittings and connectors as recommended by the manufacturer to ensure smooth operation.

- Pressure Testing: Perform regular pressure testing to identify any leaks or weaknesses in the pneumatic system. This will help you address potential issues before they lead to costly downtime or accidents.

Common Problems and Troubleshooting Tips

Despite proper installation and maintenance, pneumatic systems may encounter some common problems.

- Air Leaks: Air leaks can significantly affect the performance of a pneumatic system. Inspect the fittings, connectors, and joints for any signs of leaks.

- Pressure Drops: If you notice a sudden drop in pressure, check for any restrictions or blockages in the pneumatic pipes. Clean or replace any clogged filters, and ensure that the pipes are free from kinks or bends that may hinder airflow.

- Excessive Noise: Excessive noise in a pneumatic system can indicate a problem with the pipes or fittings. Inspect the system for loose or worn-out components, and replace them if needed. Additionally, consider using noise-reducing accessories, such as mufflers.

- Inconsistent Operation: If your pneumatic system is not operating consistently, check for any moisture or condensation build-up in the pipes.

Pneumatic Pipe 12mm Per Foot the Right Choice for Your Needs

Pneumatic pipes with a 12mm per foot measurement offer a versatile and reliable solution for various applications in Pakistan. Understanding the different types of pneumatic pipes, their advantages, and the factors to consider when choosing them will help you make an informed decision. Proper installation, regular maintenance, and troubleshooting techniques will ensure the optimal performance and longevity of your pneumatic system. Whether you are setting up a small workshop or a large-scale industrial automation system, pneumatic pipes with a 12mm per foot measurement can meet your needs efficiently and safely.

| Weight | 0.05 kg |

|---|

1 review for Pneumatic Pipe 12mm Per Foot in Pakistan

Add a review Cancel reply

You must be logged in to post a review.

Related products

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Tractive Magnet Solenoid Electromagnet SA-2602 AC weight plunger Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Nozzle PC connector 8-3 8mmx3/8″ Pipe PC Connector Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Mindman Solenoid Valve 5way 1/4 Inch Model MVSC-220-4e1 Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

Pneumatic Pipes, Pneumatic Fittings, Cylinders, Solenoid valves and accessories Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting