Proximity Sensors 18mm PNP NC in Pakistan

₨ 900.00

- Proximity Sensors 18mm PNP NC in Pakistan, the ultimate solution for precise and reliable object detection. Designed to deliver exceptional performance, these sensors are perfect for a wide range of industrial applications.

- With their 18mm size and PNP NC configuration, these proximity sensors offer seamless integration into your existing systems, ensuring hassle-free installation and operation. The advanced technology guarantees accurate detection and quick response times, enhancing productivity and efficiency.

- Equipped with state-of-the-art features, these sensors provide optimal performance even in challenging environments. Their robust construction ensures durability, making them suitable for heavy-duty applications.

- Don’t compromise on quality or reliability. Choose the Proximity Sensors 18mm PNP NC in Pakistan for unmatched accuracy and efficiency. Boost your productivity and streamline your operations with these cutting-edge sensors.

In stock

Proximity Sensors

Proximity sensors are electronic devices that detect the presence or absence of an object within a certain range. They are widely used in various industries for automation and control purposes. One specific type of proximity sensor that is gaining popularity is the Proximity Sensors 18mm PNP NC in Pakistan. In this comprehensive guide, I will provide an in-depth understanding of this sensor and its applications in Pakistan.

Understanding the 18mm PNP NC Proximity Sensor

The Proximity Sensors 18mm PNP NC is a type of inductive proximity sensor. When an object enters the sensor’s detection range, it induces a change in the sensor’s electromagnetic field, which triggers an output signal. The PNP (Positive-Negative-Positive) configuration means that the sensor’s output is normally closed (NC) and is pulled high when an object is detected.

The 18mm size refers to the diameter of the sensor’s housing. The sensor can detect metallic objects within a range of up to 18mm, making it versatile for various automation tasks. It is important to note that this sensor is designed to work with a PNP compatible input, which is commonly found in industrial automation systems.

Applications of Proximity Sensors in Pakistan

Proximity sensors, including the 18mm PNP NC variant, find extensive applications across different industries in Pakistan. One of the primary applications is in manufacturing and assembly lines. These sensors are used to detect the presence of components, ensuring accurate positioning and preventing collisions. They are commonly employed in conveyor systems, robotic arms, and packaging machinery.

In the automotive industry, proximity sensors play a crucial role in safety and security systems. They are used in parking assistance systems, where they detect obstacles and provide feedback to the driver. Additionally, proximity sensors are used in anti-lock braking systems (ABS) to monitor the speed of the wheels and provide precise control.

The food and beverage industry in Pakistan also benefits from proximity sensors. They are utilized in sorting and packaging processes, ensuring proper alignment and preventing jams in the production line. Proximity sensors are also used in vending machines to detect the presence of products and dispense them accurately.

Advantages of Using 18mm PNP NC Proximity Sensors

The Proximity Sensors 18mm PNP NC in Pakistan offer several advantages that make them a preferred choice in Pakistan’s industrial landscape. Firstly, their compact size allows for easy installation in tight spaces. This is particularly beneficial in industries where machinery is densely packed, maximizing efficiency without compromising on accuracy.

Secondly, the Proximity Sensors 18mm PNP NC are highly reliable and provide accurate detection. Their inductive sensing technology ensures consistent performance even in harsh environments, such as high temperatures, humidity, and vibrations. This reliability is crucial in industries where downtime can lead to significant financial losses.

Another advantage of these sensors is their versatility. They can detect a wide range of metallic objects, making them suitable for diverse applications. Whether it is detecting small components on a conveyor belt or larger objects in a manufacturing line, the 18mm PNP NC proximity sensors deliver reliable results.

Make sure When searching for a Proximity Sensor

When selecting a proximity sensor, there are several factors that need to be considered to ensure optimal performance. Firstly, the operating principle of the sensor should match the requirements of the application. Inductive proximity sensors like the 18mm PNP NC variant are suitable for detecting metallic objects, whereas capacitive sensors are better for non-metallic objects.

The operating range of the sensor is also a critical factor. It should be selected based on the distance at which detection is required. Additionally, the size and shape of the objects to be detected should be considered to ensure the sensor can adequately detect them.

Lastly, compatibility with the existing automation system is essential. The sensor’s output type (PNP or NPN) should match the input requirements of the system to ensure seamless integration.

How to Install and Calibrate the 18mm PNP NC Proximity Sensor

Installing and calibrating the 18mm PNP NC proximity sensor is a straightforward process. Firstly, identify the appropriate location for sensor placement considering the detection requirements. Ensure that the sensor is securely mounted, using suitable brackets or mounts provided by the manufacturer.

Next, connect the sensor’s wiring to the compatible input of the automation system. Follow the manufacturer’s instructions for proper wiring connections to ensure accurate signal transmission.

Once the sensor is installed, it needs to be calibrated. This involves adjusting the detection range based on the application requirements. Most Proximity Sensors 18mm PNP NC have an adjustable potentiometer that allows for fine-tuning the sensing distance. Use a suitable tool to turn the potentiometer and observe the sensor’s response until the desired range is achieved.

Troubleshooting Common Issues with Proximity Sensors

While proximity sensors are reliable, occasional issues may arise.

- False triggering: If the proximity sensor is falsely triggering, ensure that there are no electromagnetic interferences in the vicinity. Check for loose connections or damaged wiring and rectify as necessary. Adjusting the detection range may also help eliminate false triggers.

- No detection: If the proximity sensor fails to detect objects, check the power supply to ensure it is within the specified voltage range. Verify that the sensor is properly aligned with the target objects and that there are no obstructions. If needed, recalibrate the sensor to adjust the detection range.

- Inconsistent output: If the proximity sensor’s output is inconsistent, inspect the wiring for loose connections or damage. Check for environmental factors that may affect the sensor’s performance, such as excessive vibration or temperature variations. Consider replacing the sensor if these issues persist.

Best Practices for Maintaining Proximity Sensors in Pakistan

- Regular cleaning: Dust, dirt, and debris can accumulate on the sensor’s surface, affecting its detection capabilities. Clean the sensor periodically using a soft brush or compressed air to remove any contaminants.

- Inspect for damage: Regularly inspect the sensor for any signs of physical damage, such as cracked housing or exposed wiring. Replace any damaged sensors promptly to prevent further issues.

- Monitor environmental conditions: Keep track of the environmental conditions in which the sensors are operating. Extreme temperatures, humidity, or exposure to corrosive substances can affect their performance. Take appropriate measures, such as installing protective enclosures, to safeguard the sensors.

- Train personnel: Provide adequate training to the personnel responsible for operating and maintaining the proximity sensors. Ensure they understand the correct procedures for installation, calibration, and troubleshooting. This will help minimize errors and optimize sensor performance.

Harnessing the Power of Proximity Sensors for Improved Automation in Pakistan

Proximity Sensors, particularly the 18mm PNP NC variant, have immense potential in enhancing automation and control systems in Pakistan. Their compact size, reliability, and versatility make them suitable for a wide range of applications across various industries. By understanding the principles of operation, considering the factors for selection, and following best practices for installation and maintenance, Pakistani industries can unlock the full potential of proximity sensors and achieve improved efficiency, accuracy, and productivity. Embrace the power of proximity sensors and revolutionize your automation processes in Pakistan.

| Weight | .2 kg |

|---|

1 review for Proximity Sensors 18mm PNP NC in Pakistan

Add a review Cancel reply

You must be logged in to post a review.

Related products

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Inductive Proximity Sensor NPN NC(normally close) 6-36v DC 12mm In Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Inductive Proximity Sensor NPN NO(normally open) 6-36v DC 12mm In Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

LED Light Push Button Switch LA38 203 22mm Green Tiktik in Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

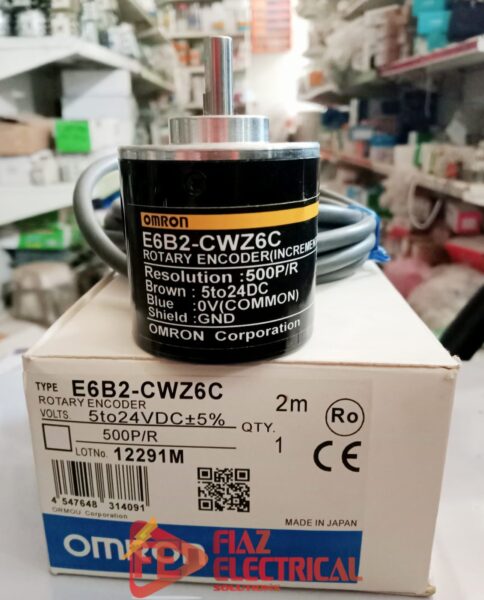

Omron Incremental Rotary Encoder E6B2-CWZ6C 360P/R in Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Tractive Magnet Solenoid Electromagnet SA-2402 AC weight plunger Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

Omron Incremental Rotary Encoder E6B2-CWZ6C 1024P/R in Pakistan

Industrial Sensors, Button, limit switches and other input devices Pakistan

MI Limit Switch Adjustable/Rotatable Roller Arm Type Mi-8108

Industrial Sensors, Button, limit switches and other input devices Pakistan

Omron Incremental Rotary Encoder E6B2-CWZ6C 500P/R in Pakistan

zain ahmad –

Nice product. Packing very good. Long lasting